Wooden Cooling Tower

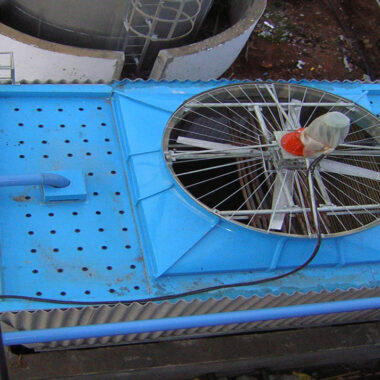

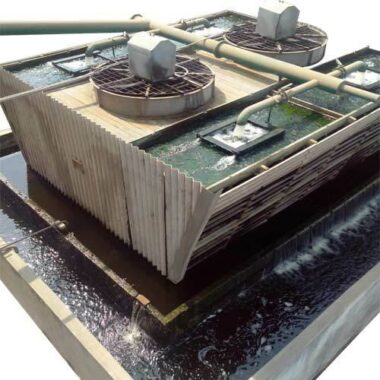

Wooden Cooling Tower design incorporates a RCC basin with number of flower type target nozzles in it and is located at the tower top. The water, by gravity, is dispersed over the fill/splash media uniformly and water is allowed to pass vertically down along wooden Splash bar. The fan coupled directly to the motor is placed horizontally to draw air across the fill media. A small portion of water is evaporated which removes the heat from the remaining water. In warm moist air is drawn to the horizontally placed fan / motor and is discharged through the fan deck, to the atmosphere. The resultant cold water is collected at the cooling tower collection sump from where it is re-circulated to the application.

The indigenous innovative was adopted by the industry for very good reason. Due to ever increasing demands for Power Generating Station and the Chemical Process Industries. The relevant Counter flow tower with wood splash bar stats become increasingly large, cumbersome and more efficient. The configuration of Cooling Tower consist of chemically Treated Timber to resist the contaminated water from the process industries. It is money saving and energy conservation strategy to over size your Cooling Tower for cold water.

Salient Features

- Easy maintenance by design

- All structural components available in HDG Steel, SS 304, and SS 316 upon request

- Adjustable pitch axial flow, dynamically balanced aluminium fans

- Casings made of wood and ACC sheet for durability and strength

- All joints fastened with SS 304 fasteners

- Uniform water dispersion through flower pot target nozzles

- Capacities range from 10TR to 1500TR in a single cell

- Water flow capacity from 5 m³/h to 1000 m³/h in a single cell

- Delta T (temperature drop) of 4°C to 20°C in a single cell

- Wooden splash bars designed for high-temperature applications (up to 80°C)

- Multi-cell designs to accommodate seasonal cooling needs

- Low pumping head requirement

- Accommodates larger variations in water flow without affecting the tower’s distribution pattern

- Easy maintenance access to distribution nozzles

- Low static pressure drop

- Reduced drift

Material of Construction for Cooling Tower Components

| Item | Material of Construction |

|---|---|

| Structure | Treated Pinewood |

| Fills | Treated Pinewood |

| Fill Support | GRP grids / G.I. grids |

| Drift Eliminator | Treated timber / PVC |

| Drift Eliminator Support | Marine plywood |

| Structural Connector | FRP rings / HDG / Wood |

| Nozzle | Polypropylene (PP), Polyethylene |

| Hardwares | HDG / S.S. |

| Nails | Twisted SS |

| Fan Assembly | Cast Aluminium Alloy / FRP |

| Fan Cylinder | FRP / HDG |

| Motor | IP 55 |

| Casing and Louvers | Corrugated AC Sheet |

| Cold Water Basin | RCC (by purchaser, as per drawing provided) |