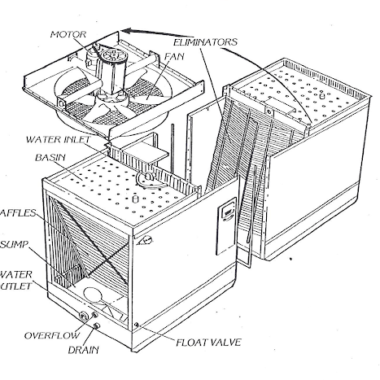

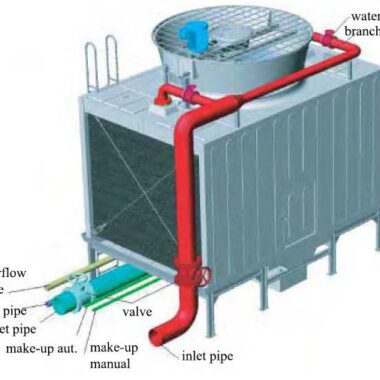

Double Crossflow Cooling Tower

Double Crossflow Cooling Tower design incorporates a FRP distribution basin with number of flower type target nozzles in it and is located at the tower top. The water, by gravity, is dispersed over the fill media uniformly and water is allowed to pass vertically down along the honey comb fills. The fan coupled directly to the motor is placed horizontally to draw air across the fill media. A small portion of water is evaporated which removes the heat from the remaining water. In warm moist air is drawn to the horizontally placed fan / motor and is discharged through the fan deck, to the atmosphere. The resultant cold water is collected at the cooling tower collection sump from where it is re-circulated to the application.

Salient Features

- Easy maintenance by design

- Does not require elaborate pillar foundations, can be placed on any flat surface

- All structural components available in HDG Steel, SS 304, and SS 316 upon request

- Adjustable pitch axial flow, dynamically balanced aluminum fans

- Casings made of FRP (Fibre Reinforced Plastics) for durability and strength

- All joints fastened with SS 304 fasteners

- Uniform water dispersion through flower pot target nozzles

- Capacities: 10TR to 1500TR in single cell

- Water flow: 5 m³/h to 1000 m³/h in single cell

- Delta T (Temperature drop): 4°C to 20°C in single cell

- ABS fills for high-temperature applications (up to 80°C)

- Lighter operational weights and reduced space requirements

- Future expansion possible with adaptation to existing towers

- Multi-cells designed to accommodate seasonal cooling needs

- Low pumping head

- Lower first-cost pumping systems

- Lower annual energy consumption and operating costs

- Accommodates larger variations in water flow without affecting tower distribution

- Easy maintenance access to distribution nozzles

- Low static pressure drop

- Reduced drift

- Reduced recirculation

- Increased air per fan horsepower

- Lower energy and operating costs

Applications on Double Crossflow Cooling Tower

- Hospitals

- Malls

- Theaters

- Air-conditioned halls

- A/C plants and cold rooms

- Chemical industries

- Dairy, citrus, and other food processing industries

- Distilleries and breweries plants

- Industrial heat processes

- Oil refineries

![images[1][8]](https://www.uaeheatexchangers.com/wp-content/uploads/2024/10/images18-380x283.jpg)