Closed Circuit Hybrid Cooling Tower

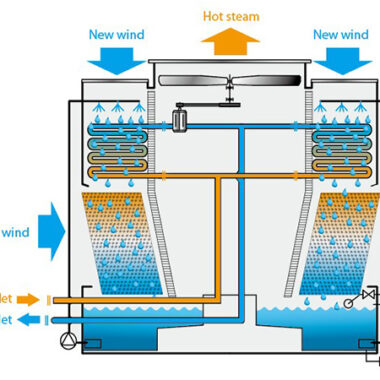

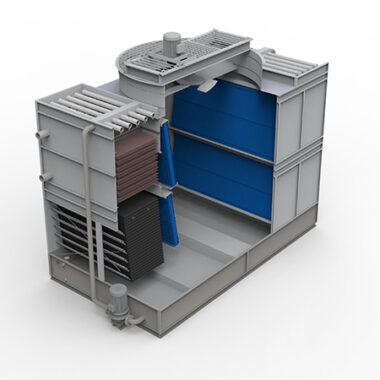

Closed Circuit Hybrid Cooling Tower deliver fully rated thermal performance over a wide range of flow and temperature requirements. Distinct advantages of the Hybrid include plume abatement, significant water savings over traditional water-cooled equipment, and its suitability for high temperature cooling (>80 °C). First, the process fluid is circulated through the dry coil. A portion is of the heat is rejected to the air passing over the dry coil.

The process fluid then enters the wet coil where the remaining heat of the process fluid is transferred through the tube wall to the water cascading downward over the tubes. Simultaneously, air is drawing in through the air inlet louvers at the base of the cooler and travels upward over the coil opposite the spray water flow. A small portion of the water is evaporated which rejects heat. The warm moist air is drawn to the top of the closed circuit cooler by the fan and is discharged to the atmosphere. The remaining water falls to the sump at the bottom of the cooler where it is recirculate by the pump through the water distribution system and back down over the coils.

Advantages of Cooling Tower

- Energy Efficiency:

Hybrid cooling towers combine both wet and dry cooling technologies, allowing them to adjust based on environmental conditions. In dry cooling mode, they rely on air to dissipate heat, which is more energy-efficient during cooler weather. - Reduced Water Usage:

One of the key advantages of closed circuit hybrid cooling towers is their reduced water consumption. These systems use a closed-loop configuration where water is not exposed to the atmosphere, which minimizes evaporation losses. - Lower Environmental Impact:

Since closed circuit hybrid cooling towers reduce water consumption and the risk of environmental contamination, they have a lower environmental footprint compared to traditional open cooling towers. - Improved Performance in High Ambient Temperatures:

Hybrid cooling towers excel in performance during high ambient temperatures. In traditional cooling towers, the cooling capacity can diminish as the temperature rises. - Reduced Maintenance:

The closed-loop nature of hybrid cooling towers significantly reduces the chances of debris and contaminants entering the system, unlike open systems that can be exposed to dirt, algae, and other impurities from the atmosphere. - Less Corrosion and Scaling:

Since the water in a closed circuit system does not come into direct contact with external elements like dirt, dust, and other environmental pollutants, it is less prone to corrosion, scaling, or the growth of microorganisms. - Flexibility:

Hybrid cooling towers are highly customizable to meet the specific cooling demands of different industries and applications. These towers can be designed to adapt to various operational conditions by switching between dry and wet cooling modes. - Low Operating Costs:

The combination of energy efficiency, reduced water usage, and lower maintenance requirements leads to significant cost savings in the long run. Hybrid cooling towers require less electricity for pumping and fan operation, especially when operating in dry cooling mode.