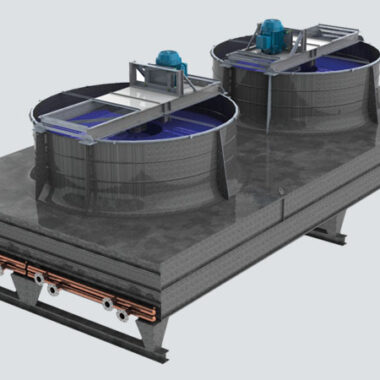

Dry Cooling Tower

Dry Cooling Towers is also known to be indirect closed loop cooling tower. Dry Cooling Towers has been structured in an way that water is cooled by the circulation through the finned tubes, which results in heat transfer. Due to this Dry Cooling Towers doesn’t need much of water as the water is not loosed.

he hot water from any equipment can be sent to the inlet of the Dry Cooling Towers & that hot water get Cooled and Cold water outlet from the Dry / Coil is connected to the pump, which pumps the cold water to the equipment to transfer the heat from the equipment with less Evaporation loss, Maintenance free, No need of raw Water tank & 100% free from decaling.

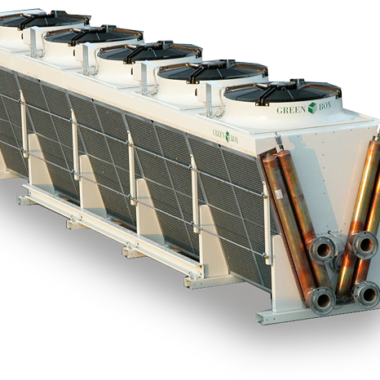

Benefits of Cooling Tower

- Conserves a significant amount of water

- Minimizes environmental impact

- Very economical in cost

Application of Dry CT

- Power Plant Cooling Solutions

- Injection Moulding

- Chemical & Oil Refineries

- Plastic Extruder Plants

- Steel Foundry & Forgings

- Dairy & Dyeing Plants

- Water Treatment Plants

- Diesel / Gas Genset Plants

Necessity of Dry Cooling Tower

Water is the most essential element of our life, About 97 percent of that is stored in ocean. Of the remaining 3%, 2% are frozen ermanently as ice. What is left is what we have to work with. And this precious and meager amount needs a lot of attention to perform its function properly in the machines of civilization. Water plays a great role in industries. It is used as a coolant in various machineries. In water cooling towers like FRP Tower or Timber Tower, huge loss of water due to drift, evaporation, spray loss and blow down. It is now abundantly clear that water charges will go on rising at well beyond inflation rates. So for that we are introducing the Dry Cooling Tower / Coil Cooling tower for save the water. You can follow us on social media as Facebook and so on.