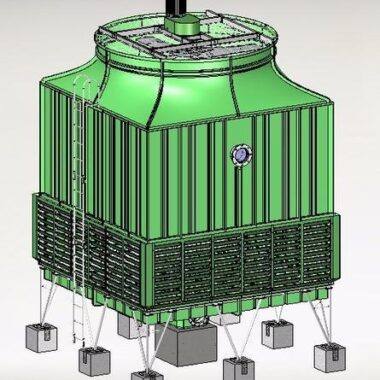

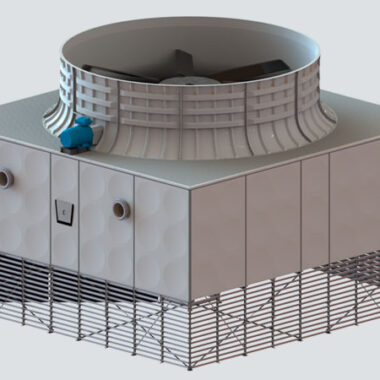

Square Shape Cooling Tower

Square Shape Cooling Towers generally offers the most effective and economical solution to most of cooling needs. TIPO has supplied numerous IDCT worldwide for all power and industry applications and all environmental conditions.

Advantages of Square Shape Cooling Tower

- Flexibility

- Cost effectiveness

- Air flow almost constant regardless of ambient air temperature

- Adapted to any water flow

- Flexible operation by shutting some cells

- Adapted to high thermal performance

- Suitable for all types of structures – wood, FRP, concrete, steel

- Compatible with all types of heat exchange surfaces, from splash grids to high-performance film

- Extremely efficient compared to forced draft cooling towers

- Employs 50% less energy compared to forced draft design

- Contains a fan located on the top, which drives air via the fills

- An inlet fan is placed on the top of the cooling tower, creating low pressure

Economical Design Taking Following Features Into Account

- Water quality

- Air environment (chemicals, dust, etc.)

- Noise and plume limitation

- Available plot area

- Local labor costs

- Employs draw-through technology

- High exiting air velocity

- Highly durable

- FRP induced cooling tower is suitable even in limited space

- Easy to clean as access is allowed from all sides

- Low piping cost due to single inlet header design

- Low design cost

- Low maintenance cost

- Available in single-cell and multi-cell configurations

Hamon can advise you on how to limit the effect of your tower on the environment in the field of

- Performance

- Drift losses

- Noise level

- Prevention of Legionella

Benefits of Square Shape Cooling Towers

- Compact design

- Corrosion resistant

- Lightweight

- Durable service life

- Maintenance-free

- Higher efficiency

- Minimum drift loss of water

- No contamination due to dust or foreign particles

- Negligible piping cost and suitable for small units

All components like Cooling Tower structure support, Motor Frame, Leg Support / Support Structure etc are eighter Hot Dip Galvanised or epoxy coated, water distribution system with GI/ PVC Pipe & Polyproplene Nozzles

ABR Polypropylene Nozzles of square shape cooling towers greatly depends upon the water distribution over the fills ABR Nozzles distribute water evenly through a wide spray angle without any dry pocket. They are lightweight and reduce the frequency of clogging. ABR also manufactures the commonly used flower type nozzles for Cross flow Cooling Towers and whirl spray type nozzles for Counter flow Cooling Towers with ½ ” , ¾ ” & 1″ threads

PVC Honeycomb type fills having extended contact area. Splits incoming air and water into several streams spread evenly across the water cross section increasing heat transfer rate easy to replace.

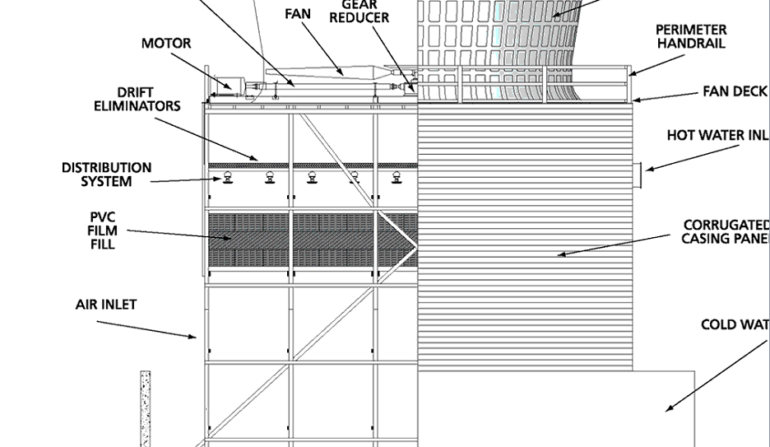

About Square Shape Cooling Towers

To give you an overview, take a glimpse of this cooling tower parts diagram below. You could see the location of the cooling tower parts and how they are connected.

The following are the cooling tower parts details including the cooling tower parts name and their functions.

Cooling Tower Louvers

Air intake louver is a part of the square shape cooling towers that serves as a block for water splash-out, noise, and debris. They also prevent the sunlight from penetrating in the cooling tower.

They could also enhance the airflow of the cooling tower and at the same time improve the appearance of the device. If the louver is not properly maintained, the cooling tower would not function well.

In case, you need louver replacement, we provide various louvers that could fit any brand and type of cooling towers. We will meet your louver needs based on your cooling tower specifications and install them properly too.

Cooling Tower Fill Media

One significant part of the cooling tower is the fill material/media. This is also referred to as the wet deck or surface.

Its main function in cooling towers is to expedite the surface area of the cooling tower to allow optimum contact between the air and the water as possible for the longest period.

The fills also make the water produce thin flowing sheets that could expose much water surface area in the contact. This could lead to larger evaporation rates.

We provide two types of fill namely the splash and film fill. They are efficient, UV protected and durable. They are also easy to install.

Cooling Tower Fan

The types of cooling towers such as counterflow, crossflow and mechanical draft have fans. The main function of these fans is to push and force the air into the cooling tower.

Most of the cooling tower fans are noisy. However, there are available fans that are quieter. It is also available to look for fans that are durable and could stand the complexity of the uses of the device.

Cooling Tower Drift Eliminators

Another essential part of the cooling tower is the cooling tower drift eliminator. This part captures the large water droplets from the air stream of the cooling tower. The water droplets contain chemicals and minerals that are affecting the environment.

Meanwhile, the drift eliminators inhibit the water droplets from getting out in the cooling tower. It alters the direction of the water droplets, which impact the blade walls and return to the cooling water.

An efficient drift eliminator keeps the undesirable loss of liquid water to less than .001% of the re-circulating water flow rate.

Cooling Tower Gear Box

Cooling tower gearboxes are needed for the big fans and powerful motors of the cooling tower. They act as reducers, in which they slow the rotational speed from the motor to the fan of a cooling tower.

The cooling tower gearboxes also serve as a torque multiplier that keeps the motor in good size. They also make the mechanical system more cost-effective. Without these gearboxes, the big and heavy motor would handle the required torque by the fan. And this would be very expensive.

Cooling Tower Float Valve

The cooling tower float valves are needed to maintain the right water levels inside the cooling tower. They regulate and control the water level, which could contribute to the lifespan of the cooling tower.

These float valves are of little maintenance too. Usually, the complete kit of float valves includes the float arm, the valve, and the float.

The installation of the float valve setting requires trial and error, in which it needs adjustment to balance the makeup water with the tower. Keep in mind that there must be no water wasted in the overflow at the closing down of the pump.

Cooling Tower Basin

The cooling tower basin may be of different types namely the collection basin and the distribution basin.

The collection basin is located below or at the bottom of the cooling tower. It aims to collect water and direct it to the sump or pump suction line.

Meanwhile, the distribution basin is a shallow-type elevated basin. It distributes hot water to the tower through orifices in the basin floor.

There is also the so-called cold-water basin that could remove stagnant water and lessens the growth of any bacteria. Its suction strainer could be easily removed and making the basin of little maintenance.

Cooling Tower Piping

Cooling tower piping chief function is to distribute water in the cooling tower. The magnitude and routing of the water piping between the heat source and the location of the tower depending on the kind of tower, site layout, and the topography.

The typical supply piping layout is that the supply line is located adjacent to the long side of the tower.

Meanwhile, vertical riser pipes are provided and connected to the supply line to the inlet connection at the elevation of the tower’s distribution system.

Cooling Tower Motor

The cooling tower motor aims to drive the fans on a type of cooling tower such as the mechanical draft cooling tower. The motors must be efficient and durable to withstand the adverse atmosphere in the tower.

There are two types of cooling tower motors namely the Open and Totally Enclosed Motors.

The open motor generates external air in the enclosure for cooling. Meanwhile, the Totally Enclosed motor inhibits the outside air from passing through the enclosure.