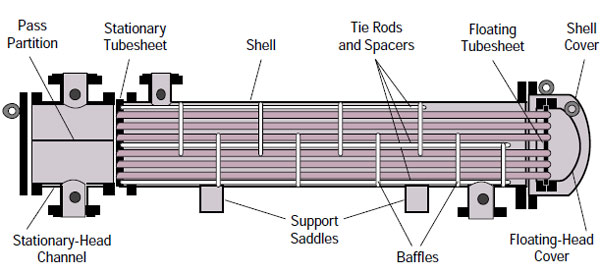

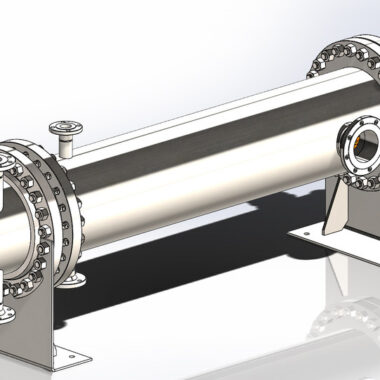

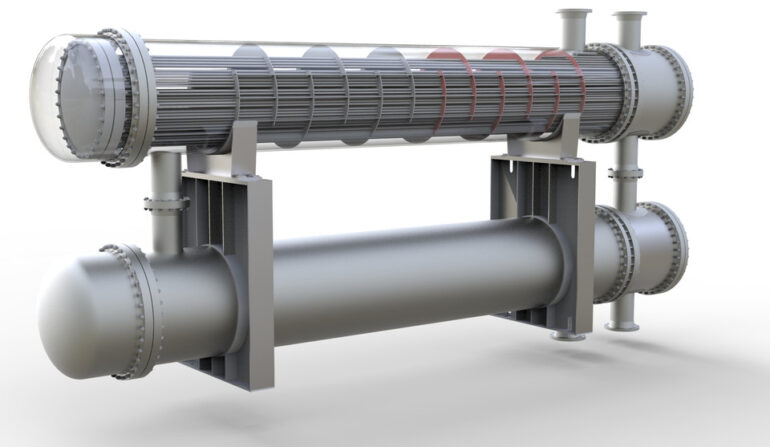

Removable Tube bundle Heat Exchanger

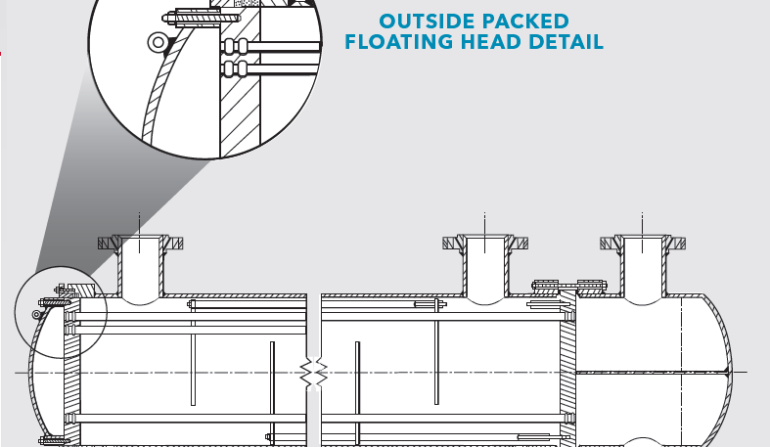

Removable Tube Bundle Exchanger is also called Floating-Head Exchanger

In a floating-head exchanger, the tube part is free to move within the system. It is a type of shell and tube heat exchanger that is typically used for high-pressure applications. This type of exchanger is more efficient than both fixed-tube sheets and U-tube exchangers, and it is also more expensive to operate. In addition, the floating-head exchanger requires more maintenance than the other two types of exchangers.

Application of Tube bundle Heat Exchanger

- General industrial applications requiring frequent cleaning

- Chemical processing applications for toxic fluids

- Hydrocarbon fluid condensers

- Special gas aftercoolers and intercoolers

- Air pollution control systems

- Secondary heat recovery solutions for returning heat to ovens, dryers, kilns

- Building heating

- OEM energy recovery applications

Floating Head Heat Exchanger Advantages

- Tube bundle can be pulled out to facilitate cleaning of the tube side and shell side.

- Temperature difference between two mediums is not limited.

- The heat exchanger can operate under high temperature and pressure (average temperature ≤ 450°C, pressure ≤ 6.4 MPa).

- Suitable for serious scaling occasions.

- Suitable for easy corrosion occasions.

- No temperature limit between the two mediums.

- Easy to clean and inspect.

- High reliability and wide adaptability.

- Suitable for dirty fluid applications due to ease of cleaning.

- The tube bundle can be removed for inspection.

- Possible mechanical cleaning of the outer surface of tubes.

- Straight tubes allow individual tube replacement.

- Tube and shell expansion is not a problem.

- The inside tube surface can be cleaned without removing the tube bundle.

- No limitation on the number of tube side passes.