Counter Flow Cooling tower – Overview

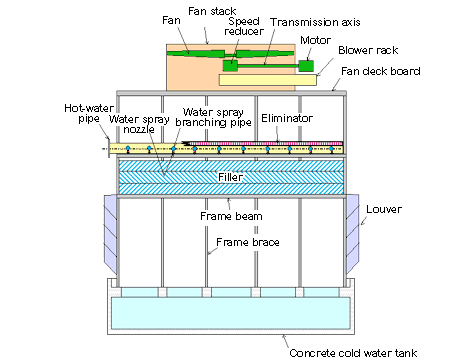

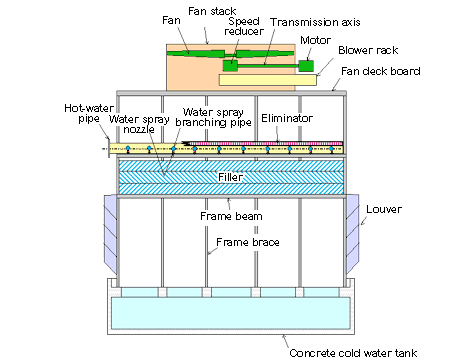

The counter flow cooling tower is a particular kind of cooling tower design that provides the highest thermal performance for its intended use. The hot water distribution basin has a horizontally mounted fill medium beneath it. As air moves through the fill, it absorbs heat from the water running down it and cools the surrounding area.

The process water stream flows in the opposite direction to the airflow, therefore the name of the design. Typically, the fan draws air through the fill media from above the water delivery nozzles (Induced draft). It might also be put in place at the tower’s air inlet section to force air inside (forced draft).

From the fill down to the cold water basin at the base of the tower, the cooled process water would flow.

As a dependable supplier of cooling tower products, we offer you a range of counter flow cooling tower options to fit your application needs.

Advantages of Counter Flow Cooling Tower

- These cooling towers are ideal for chilly conditions where icing is a risk to the device’s health and operation.

- Lower pump head and power requirements are needed for the counter flow cooling tower.

- Additionally, they function well and need little upkeep.

- Splashing and film fouling from the fills are also unlikely.

- Finally, as was already mentioned, they take up less room than the cooling they offer.

- The longer the ranges and closer the approach, the taller the tower.

- Due to pressure sprays’ finer droplet size, air is used more effectively.

Features of Counter Flow Cooling Tower

- Space-efficient design

- Maximum thermal performance from given plan area

- Can help minimize pump head requirements

- Wide choice of models, cell sizes and components

- Choice of Steel or fiberglass composite structure