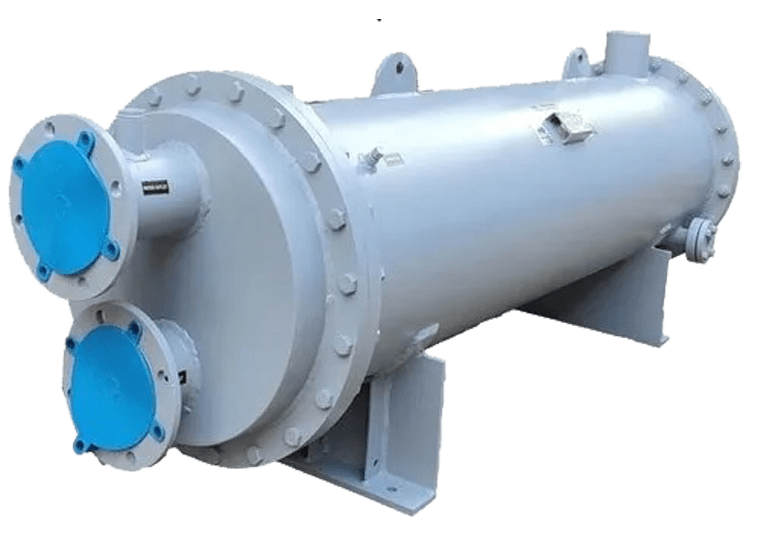

The Working Principle Of Shell and Tube Heat Exchanger

The working principle of a shell and tube heat exchanger involves the transfer of heat between two fluids, one flowing inside the tubes and the other girding the outside of the tubes within a shell. Then there is a breakdown of the key steps in its operation.

1. Introduction to the Components

Shell : The remotest structure holds the entire heat exchanger assembly.

Tubes : These are the channels through which one of the fluids( either hot or cold) flows. Tubes are generally arranged in a pattern within the shell.

2. Hot and Cold Fluids

Tube Side( Hot Fluid) : The fluid that needs to either be cooled or heated flows through the tubes. This could be hot water, steam, or any other substance experiencing a change in temperature.

Shell Side( Cold Fluid) : The fluid that either absorbs heat from or imparts heat to the tube side flows around the outside of the tubes in the shell. This is generally a coolant or some other medium capable of transferring heat.

3. Heat Transfer

Thermal Contact : The heat transfer process occurs through the walls of the tubes. The hot fluid inside the tubes transfers its thermal energy to the tube walls.

Conduction through tubes : The heat also conducts through the tube walls to the colder fluid girding the tubes in the shell.

Temperature Equalization : As a result, the temperature of the hot fluid decreases while the temperature of the cold fluid increases. The heat exchange continues until the two fluids reach a thermal equilibrium.

4. Flow Patterns

Parallel or counterflow : The arrangement of tubes and the inflow direction of the hot and cold fluids can vary. In a parallel inflow, both fluids move in the same direction. In counterflow, they move in contrary directions, which frequently maximizes heat transfer effectiveness.

5. Effectiveness Considerations

Baffles : Internally, baffles may be present in the shell to guide the inflow of the shell-side fluid and enhance heat transfer.

Fins or enhancements : Some tubes may have fins or other advancements to increase the surface area and improve heat transfer effectiveness.

6. Applications

Versatility : Shell and tube heat exchangers are versatile and find applications in various industries, including petrochemical, HVAC(heating, ventilation, and air conditioning), power generation, and chemical processing.

7. Maintenance

Cleaning and inspection : Regular maintenance involves cleaning the tubes to prevent fouling and inspecting the entire system for any signs of wear and tear or damage.

In summary, working principle of a shell and tube heat exchanger operates by allowing heat to move from one fluid( inside the tubes) to another fluid( outside the tubes within the shell) through the tube walls. This process enables effective temperature regulation in various industrial and commercial applications.

[…] Shell and tube heat exchangers stand as stalwarts within the realm of thermal building, encouraging the productive transfer of heat between liquid streams. Let’s delve into the basic principles fundamentals of Shell and Tube Heat Exchangers: […]

[…] Shell and tube heat exchangers are one of the foremost common and flexible sorts of heat exchangers utilized in different businesses around the world. Their strong plan, productive heat transfer capabilities, and flexibility to a wide extend of applications make them irreplaceable in forms requiring thermal energy exchange between fluids. In this introductory guide, we’ll investigate the elemental standards, components, working standards and introduction to shell and tube heat exchangers. […]

[…] shell and tube heat exchangers includes careful thought of different variables to guarantee ideal performance and efficiency. Here […]