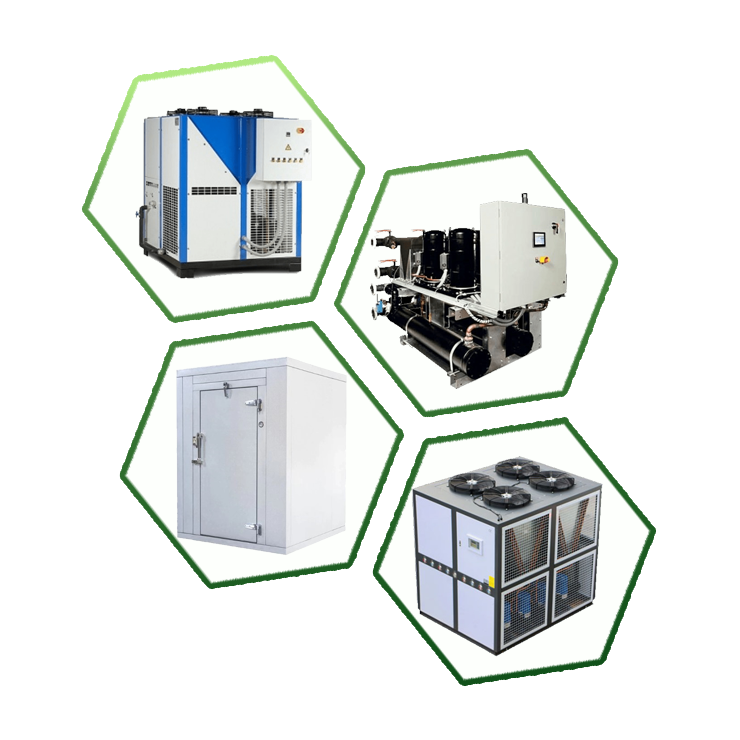

Chillers Used For Industrial Estate

The use of industrial chillers has increased dramatically over the last many times. This is because they’re extremely effective and cost-effective. They can be used in a wide range of diligence, especially those that bear large amounts of chilling processes. The choice of chillers for an industrial estate depends on factors such as the scale of operations, cooling conditions, energy effectiveness pretensions, and the types of processes involved. Then are some common types of Chillers Used For Industrial Estate :

1 Water- Cooled Chillers :

Water- cooled chillers are frequently used in industrial settings where a reliable and consistent cooling source is needed. They’re suitable for applications with a steady water force and where space permits the installation of a cooling tower.

2 Air- Cooled Chillers :

Air- cooled chillers are suitable for industrial estates where water vacuity or water quality is a concern. These chillers use ambient air for heat rejection, eliminating the need for a cooling tower. This is one of the most Common types of Chillers Used For Industrial Estate.

3 Screw Chillers :

Screw chillers, with their trustability and effectiveness, are generally used in industrial processes where medium to large cooling capacities are needed. They’re well- suited for applications with varying loads and can handle the demands of industrial products.

4 Centrifugal Chillers :

Centrifugal chillers are chosen for large industrial estates with high cooling capacity conditions. These are frequently employed in industries similar to petrochemicals, manufacturing, and power generation.

5 Process Chillers :

Process chillers can be customized to handle specific temperature ranges, fluid types, and production conditions. Process chillers are generally used in applications similar to plastics manufacturing, food processing, and pharmaceutical production.

6 Modular Chillers :

Modular chillers are suitable for industrial estates that require scalability and flexibility. These systems consist of multiple lower units that can be added or removed based on cooling demand. They offer redundancy and can acclimatize to changing industrial conditions.

7 Absorption Chillers :

Absorption chillers, driven by a heat source, are chosen in industrial estates where waste heat is readily available. They’re used for operations where both cooling and heat recovery are essential, making them energy-effective results.

When opting for chillers for an industrial estate, it’s essential to conduct a thorough assessment of the cooling requirements, available resources, and the characteristics of the industrial processes involved. Consulting with HVAC( Heating, Ventilation, and Air Conditioning) masterminds and specialists can help ensure that the chosen chillers align with the specific requirements of the industrial estate.

[…] Industrial chillers are specialized refrigeration systems designed to remove heat from a process or space to maintain a lower temperature. They are widely used in various industries for cooling processes, machinery, and facilities. The types of industrial chillers vary based on their design, refrigeration cycle, and application. Here are common types of industrial chillers: […]