Shell and Tube Heat Exchangers Application

As the industry continues to focus on energy efficiency and sustainability, heat exchangers have become essential components in many processes. Among the different types of heat exchangers available, shell-and-tube heat exchangers stand out for their versatility and efficiency. They are highly customizable and come in different types to suit different applications. This includes different flow types, head configurations, tubesheets, and materials.

Role of shell and tube heat exchangers in industry:

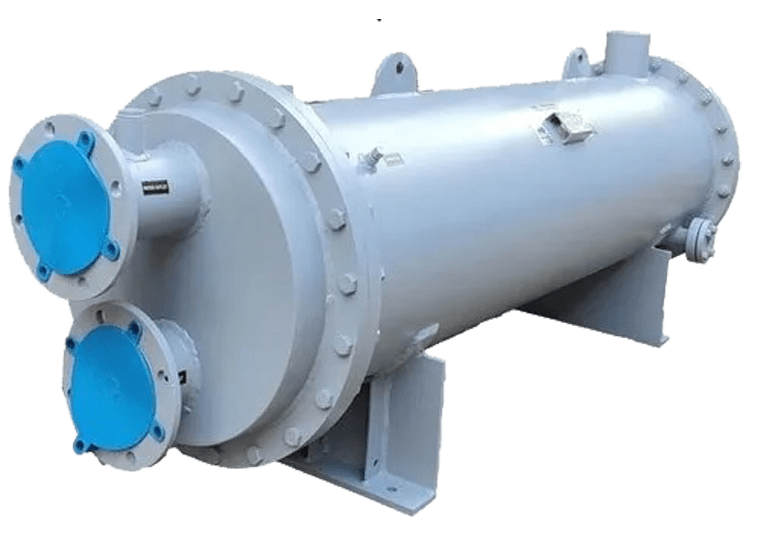

These heat exchangers consist of multiple parallel heat exchanger tubes. A tube sheet is used to securely hold this heat transfer tube. These tubes are placed inside the cover. A shell-and-tube heat exchangers Application consists of a shell or large pressure vessel that transfers heat between two different liquids, with one liquid passing through the tubes while another liquid passes through the shell.

Applications of shell and tube heat exchangers:

1. Chemical treatment:

It can handle a wide range of temperatures and pressures, making it suitable for a variety of chemical reactions.

2. Petrochemical industry:

Used for heating and cooling liquids in distillation columns, condensing vapors, and other heat transfer applications in refineries.

3. Power generation:

These are often used as condensers in steam power plants, helping to convert steam back to water for reuse in boilers.

4. Oil and gas industry:

These include processes such as crude oil cooling, natural gas processing, and heat recovery at various refineries.

5. Marine applications:

Due to their robust design and efficiency, shell-and-tube heat exchangers are used in marine applications such as marine engine cooling and heat recovery systems.

6. HVAC system:

These are used in air conditioners, chillers, and heat recovery systems.

7. Refrigeration:

In cooling systems, tube bundle heat exchangers are used to release or absorb heat, depending on the refrigeration circuit.

8. Food and beverage industry:

These include processes such as pasteurization, sterilization, and cooling. Used to adjust the temperature of liquids in food processing.

9. Pharmaceutical industry:

It is used to heat or cool a reaction mixture or to maintain specific temperature conditions during various stages of production.

10. Waste heat recovery:

This allows the recovered heat to be used for other uses within the facility, increasing overall energy efficiency.

Shell-and-tube heat exchangers Application are popular in a variety of industrial applications where heat transfer is important because of their versatility, efficiency, and adaptability.

[…] or counterflow : The arrangement of tubes and the inflow direction of the hot and cold fluids can vary. In a parallel inflow, both fluids move in the same direction. In counterflow, they move […]

[…] upgrade methods for shell and tube heat exchangers are vital for optimizing heat transfer and moving forward overall execution. Efficiency […]

[…] shell and tube heat exchanger could be a type of heat exchanger that comprises of a cylindrical shell (outer vessel) containing a […]

[…] Shell-and-Tube Heat Exchangers: Ideal for high-pressure and high-temperature environments, common in chemical and power plants.Shell and Tube Heat Exchangers Application […]