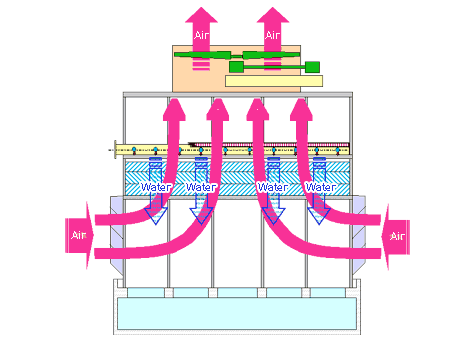

Cross Flow Cooling tower

The process water is driven down the fill medium in the opposite direction of the airflow, as shown in the diagram below. The process water is delivered to the nozzles through pressurized pipes to avoid back-flow of the water into the nozzles. Since the airflow in this manner could disturb the flow of water down to the cold water basin.

Due to the pressure differential created by the fan at the top of the tower. In this design, the air is drawn into the tower through louvers that are placed above the cold water basin. This design becomes space efficient. Since the entire horizontal cross-section of the tower is used for the distribution of the process water.

Working Principle

The counter flow cooling tower operates on the same principles as other cooling towers do in general. The water surface area increases as it passes through the fills and water. Through convective heat transfer to the moving air, it cools down.

Water is evenly distributed across the fill material by cross-flow gravity as it passes through the nozzles. A design known as a cooling tower is one in which the airflow is parallel to the water flow. To meet the fill material, air flow enters one or more of the cooling tower’s vertical faces. Through the fill and past the water flow, the cross-flow of air continues into an open plenum volume. By gravity, water passes through the fill. Near the top of a crossflow tower is a distribution or hot water basin that consists of a deep pan with holes or nozzles in its bottom.

Advantages Of cross flow Cooling tower

- Water distribution allows smaller pumps and Non-pressurized spray simplifies variable flow.

- Lower initial and long-term cost, mostly due to pump requirements.