Freon Chiller Advantages

- Efficient cooling

- Versatility

- Compact size

- Low maintenance

- Cost-effective

- Environment-friendly

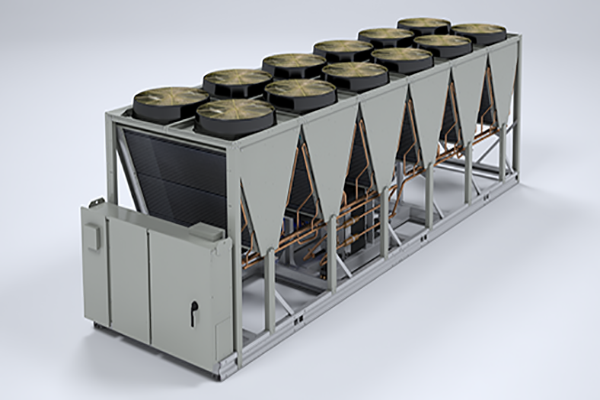

Freon chiller is a refrigeration system. It uses Freon gas as the refrigerant to cool a variety of industrial and commercial processes.

- Efficient cooling: Freon chillers are highly efficient at cooling large industrial processes due to the high specific heat capacity of Freon gas. This allows the chiller to quickly cool large volumes of material.

- Versatility: Freon chillers can be used for a variety of industrial processes. Including, cooling plastics during injection molding, cooling industrial lasers, and cooling food processing equipment.

- Compact size: Freon chillers are often smaller than other types of chillers due to their high efficiency. This can make them a good option for companies with limited space.

- Low maintenance: Freon chillers are designed to be low-maintenance, with few moving parts and long-lasting components. This can help reduce operating costs and downtime due to maintenance.

- Cost-effective: Freon chillers are often more cost-effective than other types of chillers. Due to their efficiency, versatility, and low maintenance requirements.

- Environmentally-friendly: Freon chillers use ozone friendly refrigerants that have minimal impact on the environment.

Overall, Freon chillers offer a range of advantages and features that make them a good choice for industrial and commercial cooling applications.

Working Principle Of Freon chillers

The chiller working as circulating Freon through a series of evaporator and condenser coils. The Freon absorbs heat from the air or liquid being cooled in the evaporator. Then releases that heat in the condenser. The cooled air or liquid is then distributed through the building or process.

Applications Of Freon chillers

Freon chillers are commonly used in a wide variety of applications,

- Air conditioning

- Process cooling

- Data center cooling

- Ice rinks

- Beverage production