COMPONENTS OF CHILLER COMPRESSOR

CHILLER

COMPONENTS OF CHILLER COMPRESSOR Chiller is a type of cooling system used to generate fluids that can lower temperatures by absorbing heat.

COMPONENTS OF CHILLER COMPRESSOR

MAIN COMPONENTS OF CHILLER

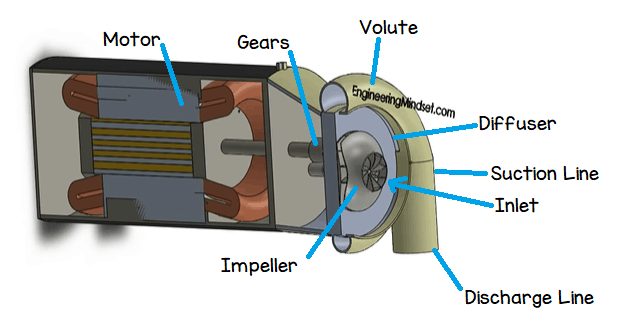

COMPRESSOR

It creates a pressure difference to move the refrigerant around the system. The centrifugal, screw, scroll, and reciprocating type compressors are the most popular designs of refrigerant compressors. It typically has partial insulation and an electric motor installed either internally or outside that serves as the driving force.

COMPONENTS OF CHILLER COMPRESSOR

COMPONENTS OF CHILLER COMPRESSOR

CONDENSOR

You’ll find the condenser after the compressor and before the expansion valve. The condenser’s job is to expel heat from the refrigerant that was absorbed in the evaporator. Condensers can be classified as either air-cooled or water-cooled.

EVAPORATOR

Between the expansion valve and the compressor is where you’ll find the evaporator. Its function is to gather the building’s waste heat. Move this into the refrigerant as well so that it can be discarded and sent to the cooling tower. As the heat is absorbed by the refrigerant, the water cools; this “chilled water” is then pumped around the structure to produce air conditioning. The “Chilled water” then makes its way back to the evaporator, carrying any extra heat from the structure with it.

POWER UNIT

The power unit can be attached to the chiller directly or it can be mounted separately on the wall of the plant room and connected by power cables. The purpose of the power unit is to control the flow of electrical power to the chiller. These usually contain a starter, circuit breakers, speed controller and power monitoring equipment.

CONTROLS

Typically, the controls unit is located on the chiller. Its goal is to keep an eye on the many parts of the chiller’s operation and regulate them through modifications. To protect the controls unit from harm, the controls unit will produce alarms for the engineering teams and safely shut the system down.

WATER BOXES

The evaporators and condensers of water-cooled chillers are mounted with water boxes. The water box’s functions include flow control and separating the entrance from the exit. The number of passes in the evaporator and condenser will determine whether water boxes have 1-2 bolted entrance or exit holes or whether they are entirely sealed off and simply divert flow back into the following pass.