Double Pipe Heat Exchangers

Double Pipe Heat Exchangers

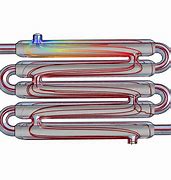

CONSTITUTION: Two sheets of guide boards 4, having recessed parts 6, 6′, a meandering recessed part 7 corresponding to an outer tube of a double tube and becoming later a cooling water passageway and a recessed parts 8, 8′ becoming later an inlet and an outlet of the cooling water, are put on together so as to pinch the inner tube 5 and the whole peripheries of both of the sheets are fixed together by welding or the like. In this case, a recessed part 9 is provided in one place at either a curved part or a straight line part of the recessed part 7 to regulate a position of the inner tube 5. According to such a method, the curved part of the outer tube may be formed easily and a meandering double tube type heat exchanger may be obtained as well.

Double pipe heat exchangers are used in many industrial processes, cooling technology, refrigeration device, sustainable energy applications and another field. Different classification of Double…The heat transfer and fluid flow characteristics of nanofluids in a double-pipe heat exchanger remain relatively unexplored. The earlier researchers estimated heat transfer coefficient of different volume concentrations of different kinds of nanofluid under laminar and turbulent flow condition.

Double Pipe Heat Exchangers